A celebration with a lot of history: video of the CENTENARY of Paniker

It’s always good to remember the good times: we share the video of the Paniker Centenary celebration, which took place at the Barcelona Maritime Museum.

It’s always good to remember the good times: we share the video of the Paniker Centenary celebration, which took place at the Barcelona Maritime Museum.

Paniker will once again be present at DJAZAGRO 2022, one of the most important fairs in Algeria.

You will find us at stand C-A 017 from May 30th to June 2nd, 2022.

Together with our official distributor in Algeria YORK ADHESIVE, we will offer you all the information about our hotmelts, water-based, solvent-based and PU adhesives.

Paniker will be exhibiting at HISPACK 2022 in Barcelona from 24th to 27th May.

You will find us at booth D196.

We’ll be introducing the most advanced technology in hotmelt and water based adhesives for packaging and labeling.

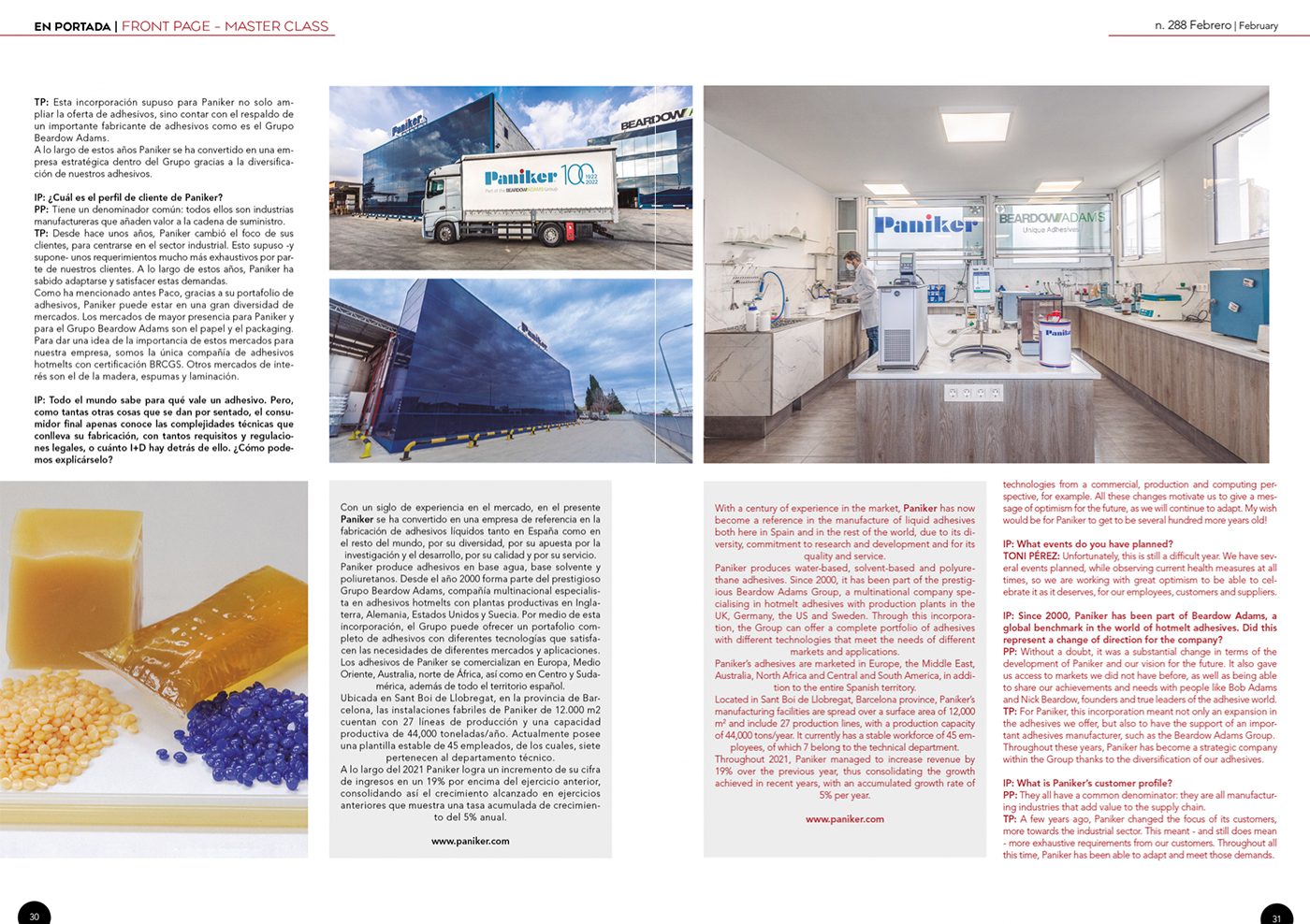

Entrevista a Toni Pérez, director general, y Paco Pérez, consejero delegado y responsable de I+D de Paniker.

Puedes leer el articulo entero aquí.

El 3 de febrero de 2022 alcanzó la mágica y centenaria cifra esta empresa barcelonesa dedicada a los adhesivos que inició su andadura en el mercado para dar servicio a la industria del cuero y el calzado y que hoy, convertida en toda una “Ingeniería en Adhesivos”, proporciona sus soluciones a mercados tan variados como exigentes, como el automóvil, la madera, las espumas, las artes gráficas y, por supuesto, el packaging y el etiquetado, tanto de dentro como de fuera de nuestras fronteras. Para conocer más sobre Paniker, en este contexto global de postpandemia en el que a todo el mundo le ha tocado reinventarse o resituarse, hablamos con Toni y Paco Pérez, director general y consejero delegado y responsable de I+D de Paniker, respectivamente.

On February 3rd 1922, Paniker’s career began in the sector of chemical products related to leather and footwear.

Today, 100 years later, Paniker has become the manufacturer of liquid adhesives, which is a benchmark both in Spain and in the rest of the world, due to its diversity, commitment to research and development, quality and service.

With 27 production lines and a capacity of 44,000 tons/year, Paniker produces water-based, solvent-based and polyurethane adhesives and is part of the Beardow Adams Group, with a complete portfolio of high class hot melt adhesives.

We invite you to know all our history and our trajectory through the following link.

Circular economy is an economic concept deeply connected with sustainability, whose main objective is maintaining the value of products, materials and resources (water, energy) in the economy for as long as possible, minimizing waste generation.

The products we consume, might have a linear or circular life cycle, depending on their ability to be classified and recycled. According to its design, with a recycled product or package, raw materials could be obtained and new products or packages can be manufactured.

Organizations such as Ecoembes (Spain), propose recommendations to design packaging that facilitate their recycling. Among these recommendations, the use of adhesives soluble in water at 85oC is suggested.

At PANIKER, almost 100% of our water-based adhesives are dispersible. This means that they positively help in recycling or, at least, do not interfere with this process.

Our grades of water-based adhesives EUROPANOL and TISSUECOL, widely used in different industries of paper, cardboard, wood (folding-gluing machines, tube winding, plywood), are examples of products that work within this sustainable scheme.

As manufacturers of water-based glues for different types of packages, we provide upon request, a certificate of dispersibility issued by our Laboratory.

From our R + D + I Department as well as from our GREEN TEAM, we continue working to provide our clients customers with products that add value to their processes.

If you want more information about our dispersible adhesives, send us your query.

In PANIKER, we believe that adhesives can contribute to the sustainability of our planet by providing efficient solutions for the Tissue industry.

Check out our new publication at TissueMAG.

We analyze the main challenges in the glues and adhesives industry.

Interview to Francisco Pérez, Non Executive Director of Paniker.

2020 has been a year that has changed us in every way. What change would you highlight as most relevant?

This Pandemic has changed the way we relate to each other, but it has given us a spirit of collaboration that, far from separating us, has united us with more intensity.

How did Paniker adapt to the new way of working?

The entire Paniker team, which includes myself, has changed the way of working in order to adapt to the needs

of this new reality.

For example, in terms of safety, we have expanded and reinforced our protocols related to PPE (personal protective equipment) concerning people and vehicles, both for collaborators and external personnel, adding more precautions to those we already have as a company of the chemical sector.

We also implemented remote work for all non-essential personnel, a measure we are currently supporting in accordance with the Government’s recommendations.

From Management, the focus was kept on adapting quickly to new customer requests with this new way of working while maintaining the quality and quantity of our service. From the Commercial area, we’ve tried to “be present” in the distance so our clients do not lose the fluidity in their demands towards us. From the Operations area, we reorganize the production processes according to the new security protocols. I don’t want to end this reply without thanking ALL our staff for their collaboration and involvement. Without each of you, we wouldn’t have been able to do it.

In the wake of the COVID pandemic, one of the challenges for organizations has been knowing how to recognize changes in market demands and adapt quickly and flexibly. How was this process being experienced in Paniker?

We are present in many essential markets so our priority was to strive not to break the supply chain. We know that our high production capacity, flexibility and proximity were going to be key to meeting certain demands. In this sense, Paniker was already prepared in advance: thanks to our technology and production means, from the exclusive plant for glues in the Tissue market, we were able to respond to urgent demands since we all observed an increase in the consumption of Tissue products during the pandemic.

We also observed the same in the entire line of packaging glues for food packaging. As a company philosophy, we consider our clients to be priority and unique, which is why we have always worked to have an excess of production and stock that allows us to provide service and meet all demands.

During the pandemic, the central role of the adhesives in the manufacture of products related to health was highlighted.

Indeed and we are honored to know that some of our products have become essential for health purposes, such as filters, masks, food, etc.

This year, a very important cycle is closed for you as General Manager of Paniker after 42 years. What expectations do you have for this new period?

I’d like to continue collaborating with the technical area, something that has always motivated me, personal and professionally, given my training as Chemical Engineer

Finally, knowing your great passion for sports, how did the pandemic change your way of life?

As mentioned before, it’s been a very important change because it affects the way of living and working. I am lucky since I’ve been able to continue doing a daily training from home (we conditioned a room for indoor cycling). On the other hand, my wife also accompanies me in this way of understanding life, so it has been easier.

The big change at a sporting level has been the outings with my club or competitions. However, on a personal level, I’ve been able to enjoy even more the little things in life, a Skype chat with my family, a virtual coffee with friends, spending more time at home chatting, reading and without traveling.

In a word: Appreciate more what surrounds you.

Beardow Adams Group announcement:

The past year has been a challenge for everyone in our Group and I thank you all for your hard work and commitment. Despite the challenges which the global pandemic has brought to us all, I am very happy to report that we have had very few cases of COVID-19 and thankfully everyone that has fallen ill with the virus has returned to good health.

As we continue to grow and invest, it is important that we also look at the future plans for all of our people within the Beardow Adams Group.

Around 20 years ago Paniker became part of our group and Carlos Rocamora Feliu and Francisco (Paco) Pérez Pérez were appointed to lead the company.

Carlos and Paco have worked for Paniker since the early 80’s with Paco responsible for Commercial & Technical. Carlos has managed everything from Customer Service through to Production, Logistics, Quality and Administration. In the past 35+ years they have increased the Paniker Group from €5m sales to the current level of €20m.

Over the years Carlos has been instrumental in the development of Paniker by improving processes, production flow / machinery and integrating several acquired companies, one of which is Obrador.

Paco started with Paniker as a chemist inventing adhesives for the paper market and also developed, designed manufacturing processes and the commercial model for Paniker’s tissue glues. He has led the sales growth in export markets to countries such as Morocco, Algeria, Senegal to name a few.

Carlos and Paco have decided that now is the time for them to step back from the day to day running of the business and will become non-executive directors whilst they hand over their responsibilities over the coming 18 months to their sons before retiring in full in 2022.

Alan Rocamora started with Paniker in 2012 and moved to Alicante to ultimately become the General Manager of Obrador in 2017. Over the past 5 years he has also taken on more duties from Carlos and is responsible for many of the departments in Paniker.

Toni Pérez has been with Paniker since 2011 when he started as a salesman in Andalucía. He has since assumed increased responsibility over time and currently manages the domestic sales team.

I am sure that you will join me in wishing Alan and Toni well in the successful management of Paniker; they are both keen to continue the philosophies established by Paco and Carlos with diversified markets, high performance products and a personalised approach to customers.

Best Regards

Adrian Day

Group Chief Executive Officer

Beardow Adams Group

Paniker presente en la edición de mayo 2020 del magazine internacional TissueMAG ( páginas 81 y 154-156).

TissueMAG es un publicación de distribución mundial y una referencia dentro del Sector Del Tissue.

El artículo es un repaso de nuestra compañía desde los comienzos hasta llegar a la actual PANIKER, presente en diferentes mercados y tan exigentes como el del TISSUE.

PANIKER a lo largo de estos casi 100 años de recorrido, se ha convertido en una compañía líder y de referencia en el sector de los adhesivos, gracias a su altamente cualificado Departamento de I+D+I , capaz de entender y adaptar nuestros productos a la medida de las necesidades de nuestros clientes/mercado y a todo nuestro equipo humano trabajando siempre en ofrecer el mejor servicio a nuestros clientes ( Calidad en el Servicio – Servicio de Calidad).

En el artículo también se presenta nuestra gama de adhesivos, para las diferentes aplicaciones del Sector TISSUE, Laminado, Cierre, Arrastre y Tubo , así como nuestra planta productiva exclusiva para adhesivos del TISSUE, que permite ofrecer cortos plazos de entrega.

La Sostenibilidad o Economía Circular, también tiene cabida en este artículo y es que PANIKER está muy focalizada con el cuidado con el planeta, y respetuoso con el Medio Ambiente.

Si desea obtener más información, envíe un email a la dirección paniker@paniker.com